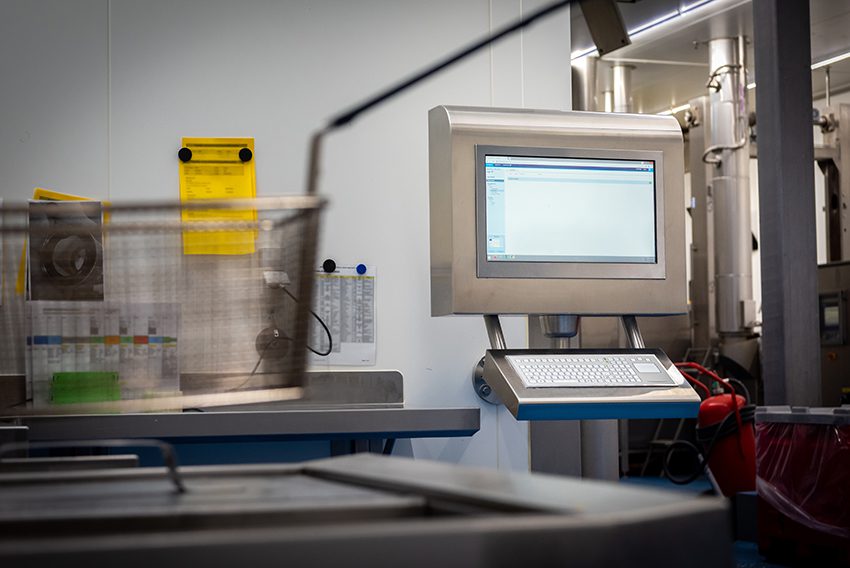

Case Human Machine Interfaces

A hygienic keyboard, resulting in a modular waterproof industrial PC.

Optimal readability at any time of the day and under all lighting conditions.

Mora was looking for an IT solution partner who could supply hygienic keyboards – easy to clean – and a display that had to be connected to Mora’s PC for testing purposes. Mulder-Hardenberg was approached and came up with a suitable alternative in which all of Mora’s wishes are integrated within one total solution. Mora liked to see their own PC integrated in one watertight housing suitable for the food processing industry, with a flexible support arm, in short an HMI total solution.

Unfortunately, in a production environment, things sometimes break unintentionally due to unfortunate actions. It is therefore seen as an advantage that the result is an HMI (Human Machine Interfaces) solution in which the structure is modular and Mora has the opportunity to replace components quickly and effectively in the event of a defect.

The challenge

Food production company Mora (part of snack producer Ad van Geloven) asked Mulder-Hardenberg for a keyboard and a monitor to which their own PC could be connected for food testing purposes. The equipment had to be robust, corrosion-resistant and watertight due to the high temperature. cleaning activities and in accordance with the requirements of the food production industry.

Since the unit had to be placed near the production line, no (protective) glass could be used for the screen. Because of the uniformity, they wanted to integrate their own standard PC or thin client. In addition, the solution had to be mounted on the rear wall with a swivel support arm so that the unit could be moved in a rotational movement and therefore always easy and ergonomically sound to operate.

The solution

Mulder-Hardenberg has found a solution for every wish. Ultimately, in consultation with Mora and in close consultation with the manufacturers of the components, an HMI total solution was chosen in which the separate components – namely a 23” screen with a touchscreen based on PE, a flat keyboard with mouse pointer and Mora’s own PC – mounted separately from each other within a rotatable stainless steel housing watertight.

This has the advantage that each component can be replaced separately as soon as a component has become defective from the outside. This prevents Mora from having to replace the entire system. A long-term saving in replacement costs and a significant reduction in the replacement period. Any downtime is thus reduced to an absolute minimum.

The execution

The robust HMI solution has a considerable weight that could not simply be carried by the ‘thin’ mounting wall behind it. To solve this, the wall is reinforced at the rear with a flat plate and watertight cable duct. The power supply and network connections are fed into the HMI via this cable entry via the support structure. Within the fully housed system, you can access the PC connections and the 23-inch touchscreen with the right tools. It is also possible to access the built-in keyboard component from the bottom of the keyboard.

The result

All of Mora’s wishes have been met and even exceeded. The workstation is experienced as pleasant to handle and can be used safely by users under all circumstances. Due to the construction, moisture and dirt cannot reach the electronics, the operation is not affected by these factors. The success of the application is not without consequences. The thin client integrated by Mora itself turned out to have a problem and was replaced by a different type by Mora himself. The fact that they were able to do this independently and the downtime was therefore limited, immediately showed that the costs of this modular solution will therefore be considerably lower. The manufacturer of the monitor, keyboard and steel housing is also more than satisfied with the input, feedback and additional specifications that have been drawn up together. An enrichment of the product specs.